Various Types of casing in Centrifugal Pumps

What Is casing in centrifugal pumps?

Casing in centrifugal pump serves to seal off the inside of the pump to the atmosphere to prevent leakage and retain pressure. In the case of centrifugal pumps, they surround the pump rotor which transmits energy to the fluid handled via the impeller mounted on the rotating shaft.

The term “casing” is generally used to describe the component that “contains” the pump. In practice a pump’s casing has five functions:

1. It will Provide pressure containment.

2. Incorporate the collector, either as an integral part of the casing or as a separate piece.

3. Permit rotor installation and removal.

4. Support the pump or provide a structural connection to the pump’s support.

5. Maintain alignment of the pump and its rotor under the action of pressure and reasonable piping loads.

There are three types of casing in a centrifugal pump are described below

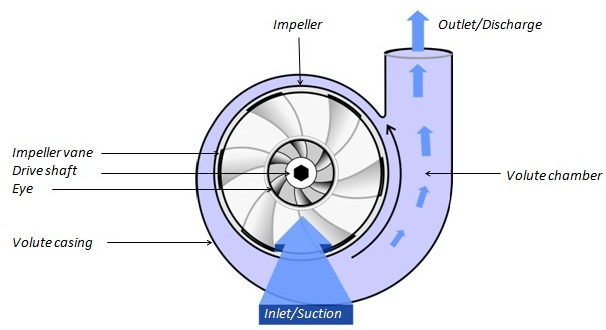

1. Volute casing

2. Vortex casing

3. Casing with guide blades

1.Volute casing

It is a spiral type in which area of flow increase gradually. The increase in area of flow decreases the velocity of flow. Decrease in velocity increases pressure of water flowing through the casing.

Volute casing is the most common type of casing

The volute casing pump is the most common type of centrifugal pump. Its characteristic feature is the volute-shaped pump casing which is typical for single-stage centrifugal pumps.

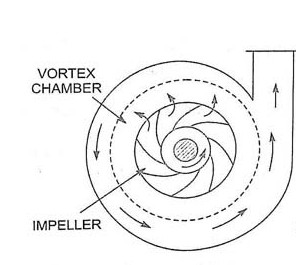

2.Vortex casing

Vortex casing is a casing in which circular chamber is provided between the casing and the impeller.

Vortex casing is helpful to increase pump efficiency by reducing eddies formation to a considerable extent.

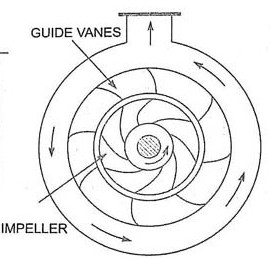

3.Casing With Guided Blades

In the casing with guided blades the impeller is surrounded by series of guide blades.

The guide blades are mounted on a ring which is called as diffuser.

The design of the guide vanes are kept as such that the water which is leaving the impeller enters the guides without shock.

The area of the guide vanes increases; this helps to decrease the velocity of the liquid and increases its pressure. After guide vanes, water passes through the surrounding casing.

In most of the cases, the casing remains concentric with the impeller.

To know More about casing in:centrifugal pump by KSB PUMP click on the link : Pump casing