Effect of Impeller Diameter on Flow, Head & Power

In pumps and turbomachinery, the impeller diameter is one of the most important factors affecting performance. The Affinity Laws explain how Flow, Head, and Power change when the impeller diameter changes, while speed remains constant.

Affinity Laws (Constant Speed, Varying Diameter):

1. Flow (Q): Q₁/Q₂ = (D₁/D₂)³

2. Head (H): H₁/H₂ = (D₁/D₂)²

3. Power (P): P₁/P₂ = (D₁/D₂)⁵

Explanation:

– Larger impellers increase flow capacity.

– Head increases with square of diameter due to velocity rise.

– Power rises sharply with fifth power of diameter.

– Impeller trimming (reducing diameter) is used to match pump duty but limited to ~10–15%.

Numerical Example with Step-by-Step Calculation:

Let’s consider a pump with:

• Original diameter D₁ = 200 mm

• Flow Q₁ = 100 m³/h

• Head H₁ = 40 m

• Power P₁ = 15 kW

Now trimmed to D₂ = 180 mm:

- Flow (Q₂):

- Q₂ = Q₁ × (D₂/D₁)³

- Q₂ = 100 × (180/200)³

- Q₂ = 100 × (0.9)³ = 100 × 0.729 = 72.9 ≈ 73 m³/h

- Head (H₂):

- H₂ = H₁ × (D₂/D₁)²

- H₂ = 40 × (180/200)²

- H₂ = 40 × (0.9)² = 40 × 0.81 = 32.4 m

- Power (P₂):

- P₂ = P₁ × (D₂/D₁)⁵

- P₂ = 15 × (180/200)⁵

- P₂ = 15 × (0.9)⁵ = 15 × 0.59049 = 8.86 ≈ 8.9 kW

Comparison Table:

| Parameter | Before (D₁ = 200 mm) | After (D₂ = 180 mm) |

| Flow (Q) | 100 m³/h | ≈ 73 m³/h |

| Head (H) | 40 m | ≈ 32.4 m |

| Power (P) | 15 kW | ≈ 8.9 kW |

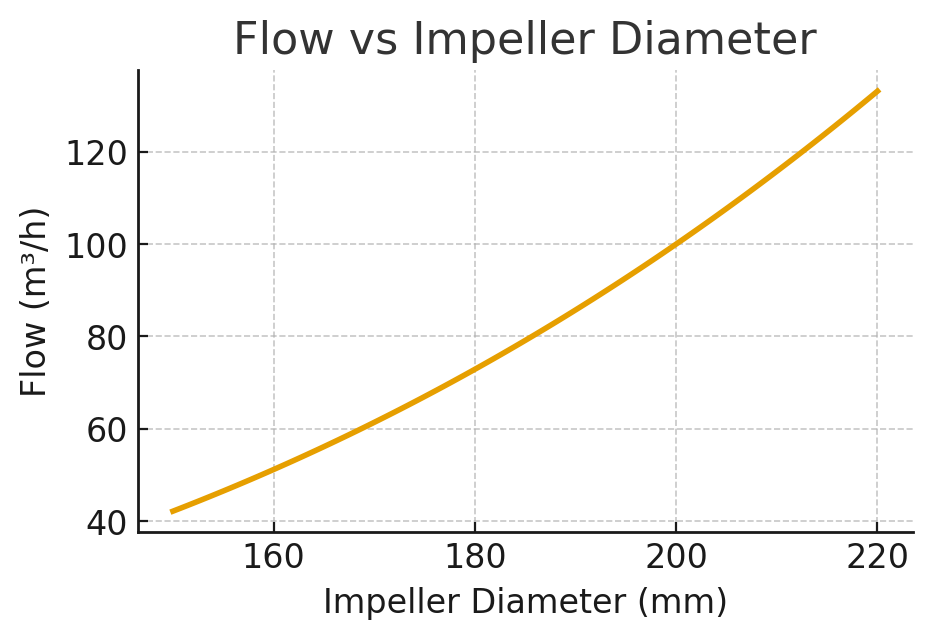

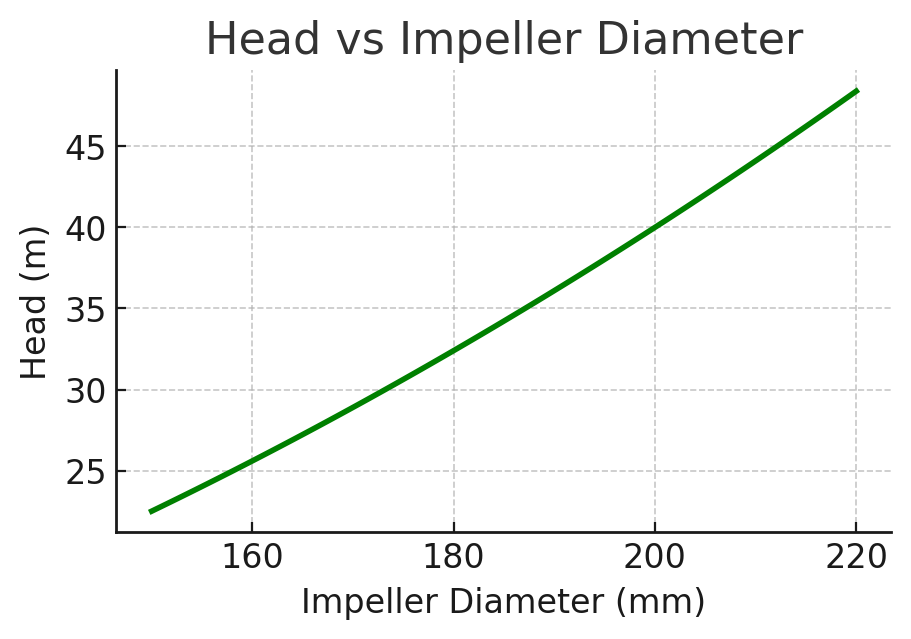

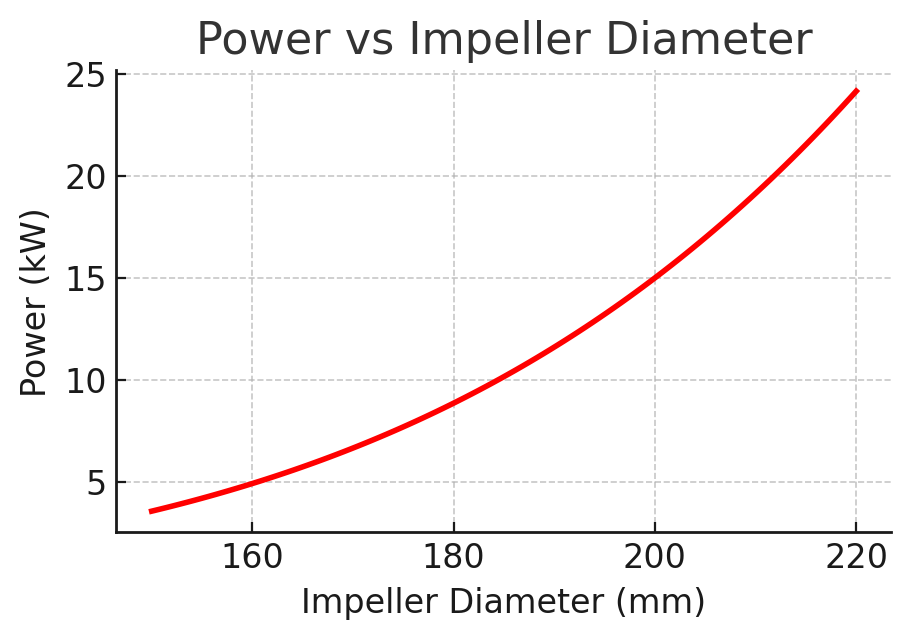

Graphs:

The following graphs illustrate how Flow, Head, and Power vary with impeller diameter.

Conclusion:

The Affinity Laws clearly show that a small change in impeller diameter results in a large impact on pump performance.

– Flow reduces with the cube of diameter.

– Head reduces with the square of diameter.

– Power reduces with the fifth power of diameter.

Thus, selecting or trimming impeller diameter is a key tool for optimizing pump energy efficiency and performance.

- Effect of Impeller Diameter on Flow, Head & Power

In pumps and turbomachinery, the impeller diameter is one of the most important factors affecting performance. The Affinity Laws explain how Flow, Head, and Power change when the impeller diameter changes, while speed remains constant. Affinity Laws (Constant Speed, Varying Diameter):…

In pumps and turbomachinery, the impeller diameter is one of the most important factors affecting performance. The Affinity Laws explain how Flow, Head, and Power change when the impeller diameter changes, while speed remains constant. Affinity Laws (Constant Speed, Varying Diameter):… - Case Study: Achieving Stable Flow Measurements in a Submersible Pump Test Bench

Project Type: Internal R&D Client: Aarohi Embedded Systems Pvt. Ltd. Location: Rajkot, Gujarat, India Overview At Aarohi Embedded Systems Pvt. Ltd., innovation and precision are at the heart of our engineering practices. During the development of a submersible pump performance test…

Project Type: Internal R&D Client: Aarohi Embedded Systems Pvt. Ltd. Location: Rajkot, Gujarat, India Overview At Aarohi Embedded Systems Pvt. Ltd., innovation and precision are at the heart of our engineering practices. During the development of a submersible pump performance test… - How do you troubleshoot 3 phase AC motor?

The table presented below provides a comprehensive insight into the frequently encountered issues that afflict 3-phase squirrel cage induction motors. It not only outlines the root causes behind these problems but also offers effective remedies to rectify them, thereby restoring the…

The table presented below provides a comprehensive insight into the frequently encountered issues that afflict 3-phase squirrel cage induction motors. It not only outlines the root causes behind these problems but also offers effective remedies to rectify them, thereby restoring the… - Types of losses in Induction Motor

The losses in induction motor are broadly categorized into two classes, namely constant losses and variable losses. Variables losses appear only in AC machines and they are temperature related. Constant losses appear only in DC machines and they are normally referred…

The losses in induction motor are broadly categorized into two classes, namely constant losses and variable losses. Variables losses appear only in AC machines and they are temperature related. Constant losses appear only in DC machines and they are normally referred… - 5 Symptoms Of Failing Electric Motor Rotor

Motors are used everywhere in industrial environments and they are becoming increasingly complex and technical, sometimes making it a challenge to keep them running at peak performance. Use this quick guide to respond quickly and confidently when any electric motor rotor…

Motors are used everywhere in industrial environments and they are becoming increasingly complex and technical, sometimes making it a challenge to keep them running at peak performance. Use this quick guide to respond quickly and confidently when any electric motor rotor… - Comparison between servo motor vs induction motor

The Technological lines separating induction motors from servo motors are beginning blur at many point’s. An induction motor is an electric motor that works on the principle of electromagnetic induction. An induction motor is the most modest electrical machine from the construction point…

The Technological lines separating induction motors from servo motors are beginning blur at many point’s. An induction motor is an electric motor that works on the principle of electromagnetic induction. An induction motor is the most modest electrical machine from the construction point…